GL3000E ultrasonic servo web aligner system :

GL3000E controller + SL150E + SG200E ultrasonic sensor

◎Reaction time 2ms, high precision;

◎System control accuracy 0.1mm;

◎ Can drive various drives;

◎It can be connected to various rectification sensors, which can realize rectification functions such as edge tracking, dual sensor centering, and line tracking;

◎Using OLED high-resolution display screen to fully control the real-time status of the system;

◎Real-time display of material deviation, driver position current, temperature;

◎Screen sleep energy saving and screen lock protection;

◎Automatic running state can quickly modify system parameters online;

◎Abundant rectification functions: serpentine oscillation rectification, multi-layer rectification, material fault tolerance, etc.

1. Processor (CPU): 32-bit high-performance microprocessor, the highest frequency is 48MHz;

2. Sensor interface: dual analog input;

3. Driver interface: support DC brushless motor driver, the maximum driving power is 240W;

4.1/0 interface: six-channel programmable remote control digital I/O;

5. Communication interface: RS485 (support Modbus-RTU protocol), which can be used for remote control;

6. Working environment: working temperature 0~-50*C; maximum humidity 5~9096, no condensation;

7. Power supply: 24V DC;

8. Protection circuit: support overcurrent, overvoltage, overload. Short circuit and power reverse connection protection:

9. Support limit alarm, fault alarm. Fault self-diagnosis.

SG-300E CCD image sensor performance and features :

This image sensor scans the material surface light contrast in real time through linear array CCD image sensing, which can realize non-contact scanning of materials .

1. Use high-speed linear array CCD image sensor elements to accurately track printing lines, printing edges or material edges;

2. Use full-color light-emitting diodes as background lighting sources. Different colors of lighting sources can be selected according to the reflective properties of the material surface to achieve the optimal lighting effect;

3. Adopt fully laminated glass capacitive touch panel, IPS high-bright color screen, menu-based operation interface, simple and intuitive;

4. Laser line-assisted positioning;

5. Configure USB storage interface to facilitate on-site tracking algorithm firmware upgrade;

6. Equipped with two output interfaces, analog and CAN communication, to facilitate integration into different correction systems;

Technical Parameters:

1. Power supply voltage: 12~30Vdc

2. Current consumption: 120mA/24Vdc

3. Output interface: analog (2~8mA) or CAN bus (system configurable)

4. Ambient temperature: 0~50°C

5. Measuring range: ±10mm

6. Resolution: 0.05mm

7. Focus distance/format spacing: 25~30mm

8. Scan rate: 500~2000Hz

9. Protection level: IP54

10. Dimensions (length x width x height): 100x68x49mm

SG-200E Ultrasonic sensor performance and features :

⊙ It can track the edges of various materials;

⊙High-precision detection, fast response

⊙Strong anti-interference ability design;

⊙ Different opening sizes and detection ranges can be customized

⊙ Detection accuracy 0.01mm

⊙ Detection range 7mm

⊙Response time 2ms

⊙Anti-light interference (infrared) sunlight 10000Lu×, fluorescent lamp/3000Lus

⊙ Opening size 40mm

⊙ 24V input

⊙ It can track the edges of various materials;

⊙High-precision detection, fast response

⊙Strong anti-interference ability design;

⊙ Different opening sizes and detection ranges can be customized

⊙ Detection accuracy 0.01mm

⊙ Detection range 7mm ⊙Response time 2ms

⊙Anti-light interference (infrared) sunlight 10000Lu×, fluorescent lamp/3000Lus

⊙ Opening size 40mm

⊙ 24V input

⊙Brushless DC motor, fast response, super long and durable;

⊙ Built-in electronic brake to ensure accurate positioning;

⊙ Built-in position feedback function, real-time accurate display of travel position;

⊙The limit and center can be set to any position through parameters;

⊙ Real-time display of drive module temperature and motor current;

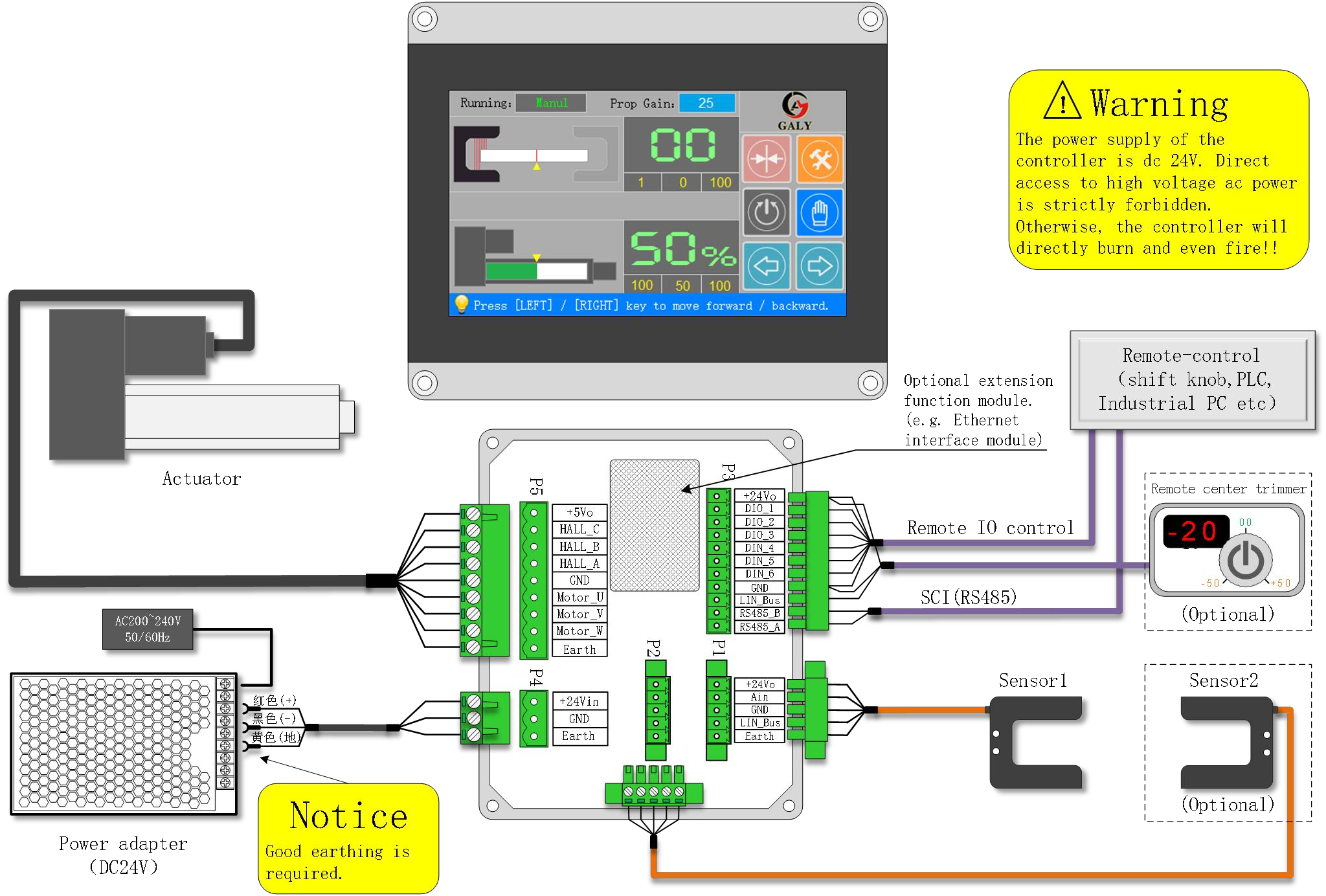

Wire Connect :

Contact: Isha

Phone: +86 17768303169

E-mail: wuxigaly@126.com 17768303169@163.com

Add: No. 522,Dadong Road,Binhu District,Wuxi city,Jiangsu Province in China