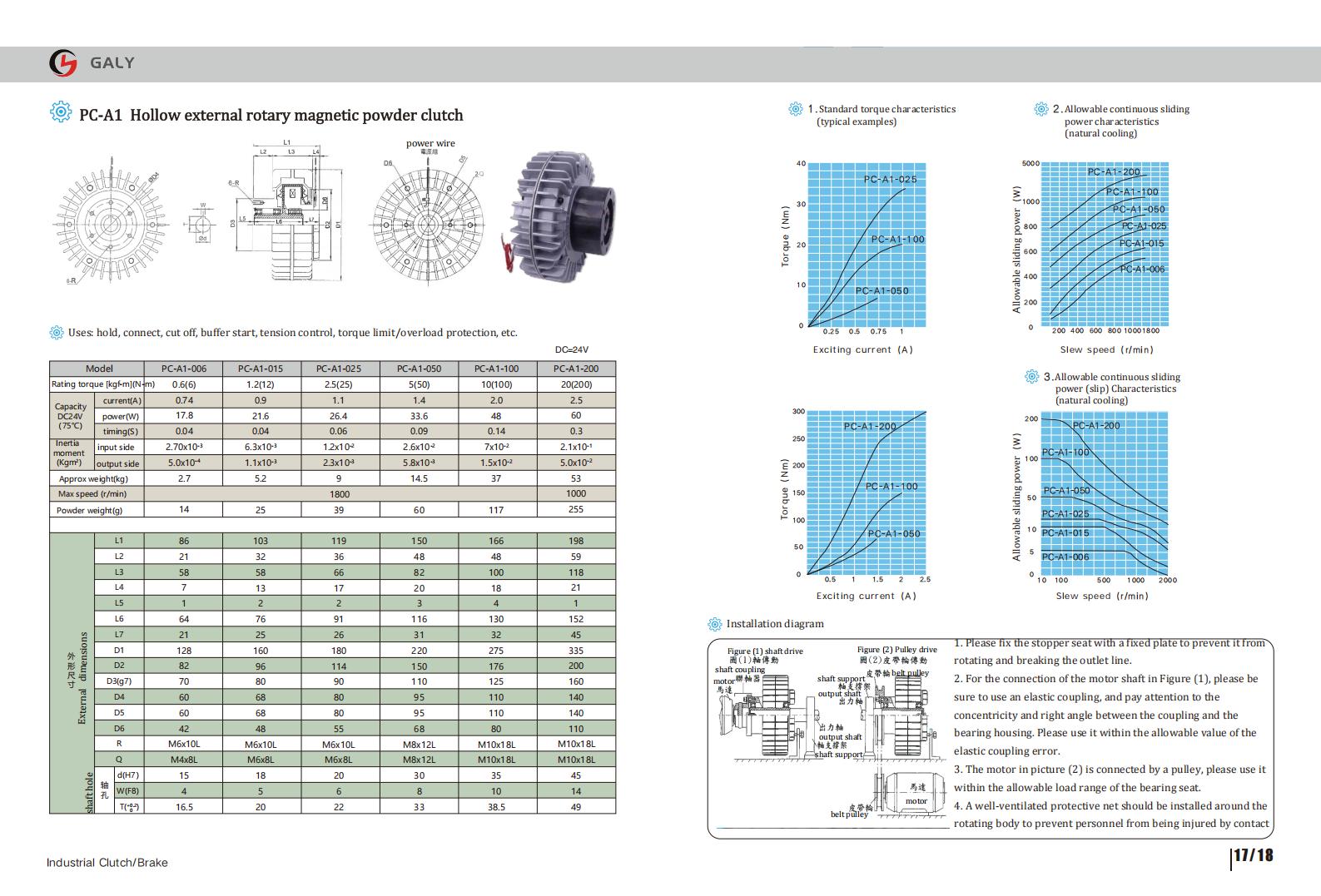

GL 24V industrial shell rotating magnetic particle clutch for tension control :

The magnetic powder brake/clutch is composed of active rotor(input shaft), driven rotor(output shaft) and Yoke with excitation coil.

The three parts are assembled relative concentric and form a system which can rotate relatively.

The annular gap between active rotor and driven rotor is full of alloy powder which has high magnetic conductivity.

Introduction of magnetic powder clutch

The magnetic powder brake/clutch is composed of active rotor(input shaft), driven rotor(output shaft) and Yoke with excitation coil. The three parts are assembled relative concentric and form a system which can rotate relatively. The annular gap between active rotor and driven rotor is full of alloy powder which has high magnetic conductivity.

Features of magnetic powder clutch

1. The user just adjust the excitation current of the magnetic powder clutch can accurately control the torque, so as to

effectively control the size of the load resistance. Usually continuous sliding friction parts will be fever, and even burn out.But

this equipment has the complete radiator, long time operation is not too hot, and long service life.

2. The friction part will generate heat inevitably or even destroyed when it keep continuous sliding. But this device has a

complete cooling set, it will not generate a lot of heat after long time running and it has a long service life.

Application of magnetic powder clutch

1. In addition, magnetic powder clutch can also be used to buffer starting, overload protection, control, etc.;

2. Magnetic powder clutch can also be used for mechanical transmission test load, brake, etc.

About life of magnetic powder clutch

The use of magnetic powder clutch/brake life lies in the life of the magnetic powder.In general, magnetic powder in the condition of not overloaded, its service life is 4500~7500 hours;But in some condition it can prolong service life many times, such as: reduce the magnetic powder clutch/brake torque, relative sliding speed and slip power to the rating of 50% 70%.That is to say, when the design, allowance enlarge some as much as possible.

About the torque of magnetic powder clutch

Magnetic powder clutch/brake factory after use, the magnetic powder in the early stages of using break-in happens, torque will be slightly down, can be adjusted by electric current to compensate.

Technical Parameter of magnetic powder clutch

Contact: Isha

Phone: +86 17768303169

E-mail: wuxigaly@126.com 17768303169@163.com

Add: No. 522,Dadong Road,Binhu District,Wuxi city,Jiangsu Province in China