Features:

1. Easy to install

2. Contains idler roller

3. Minimize deviation

4. Four rated load levels

5. Various roller width specifications

6. Eliminate the coil guidance effect

7. Can be customized according to roller width, diameter or roller surface treatment requirements

The cantilever tension sensor uses imported full-bridge strain gauges (high-precision with built-in temperature compensation) for detection, and through high-precision signal and temperature compensation processing, it has the characteristics of high precision, low temperature drift, and good linearity. The sensor can effectively shield static electricity and frequency conversion. The group pulse interference of the device. It has a built-in overload limit to prevent damage to the sensor during overload. The sensor can be equipped with different lengths such as 200mm, 300mm, 400mm, 500mm, etc. Special models can be customized if required.

Features:

1. Easy to install

2. Contains idler roller

3. Minimize deviation

4. Four rated load levels

5. Various roller width specifications

6. Eliminate the coil guidance effect

7. Can be customized according to roller width, diameter or roller surface treatment requirements

Technical parameter:

Excitation voltage: 10VDC

Output signal: 2mVN

Strain resistor resistance value: 350Ω

Strain resistor type: full bridge semiconductor

Comprehensive error of nonlinearity and hysteresis: ±0.50% of measuring range

Maximum overload capacity: 300% of rated

load Protection level: IP54

Temperature operating range: Compensation -10~55°C Operation -20~85°C

Temperature drift coefficient: Zero point temperature drift 0.015%/°C Range temperature drift 0.015%/°C

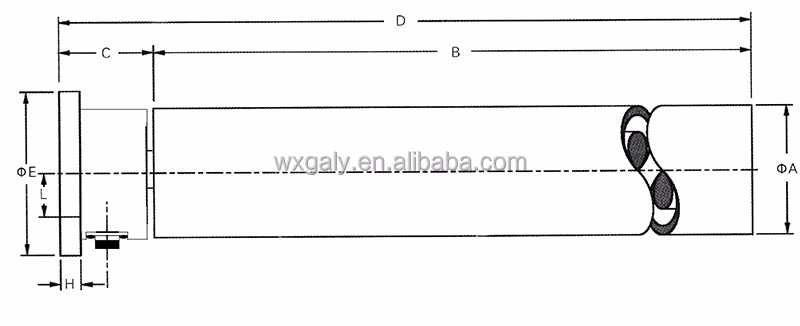

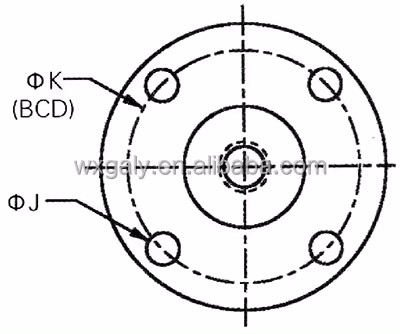

SIZE:

A and B dimensions can be customized, unit: millimeter mm ΦA:60 B:300 C:71 D:365 ΦE:90 ΦK:75 ΦJ:9

Contact: Isha

Phone: +86 17768303169

E-mail: wuxigaly@126.com 17768303169@163.com

Add: No. 522,Dadong Road,Binhu District,Wuxi city,Jiangsu Province in China